- Simultaneous equipment of the entire fleet

- Large number of vehicles and Transponders

- Changing attachment spots due to varying vehicle types

Digitalized Waste Management

Case study

Challenge

Solution

- RFID-based tooth antenna

- Waterproof trash can transponders

- Central management software

Benefits

- Enhanced process flows for improved efficiency

- Gathering usage data for better insights

- Precise determination of waste weight

Project goal

- Waste reduction and careful use of resources

- Clearly identify and account containers

- Improvement of planning reliability

Project summary

Waste reduction and more efficient use of resources thanks to transponders

The Contena-Ochsner AG has been a leading provider of waste disposal technology in the EU for 40 and 170 years, respectively. The merger of the two Swiss companies, Contena Handels AG and J. Ochsner AG, ensures that our waste is properly disposed of through their refuse collection and sweeping machines. The digitization of this process has been a crucial step in ensuring demand-driven waste disposal and increasing the planning reliability of waste collection.

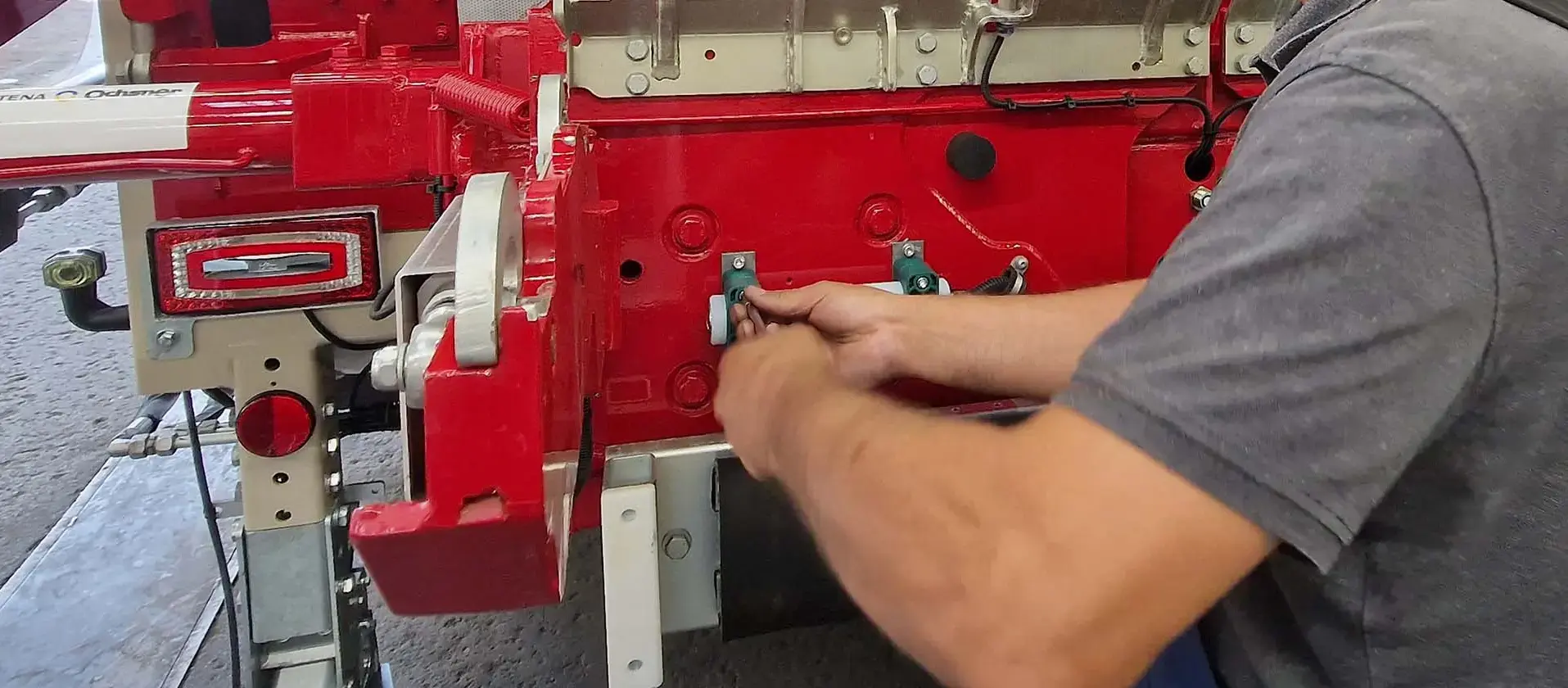

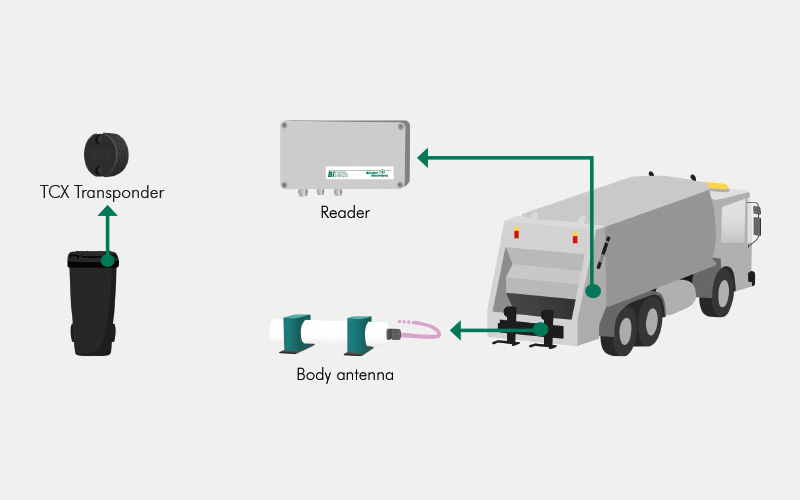

The Contena-Ochsner AG manufacture, trade, and distribute products for the entire waste management sector, particularly waste collection vehicles, waste containers, as well as specialized vehicles for container cleaning and other related products. Chip-enabled waste bins, mobile applications, and software solutions for route optimization facilitate daily work routines and make processes faster, more transparent, and more efficient. This enables resource conservation, as well as time and cost savings through the accurate identification of the number of bins and waste weight. Precise identification of waste weight ensures accurate calculation of waste collection costs. The bins are fitted with a transponder that are read directly at collection via a comb or body antenna mounted on the vehicle. The body antennas implemented in this project ensure all waste containers equipped with HDX and FDX transponders can be quickly and reliably identified, even when mixed. To ensure additional transparency and reliable capture of all dato collected, this dato is transmitted directly to the connected system. The system developed by KOCO Solutions AG records the number of bins emptied by the refuse truck and their respective weights. This demand-driven disposal approach leads to more efficient processes and increased planning reliability for waste collection. For this project, the team at Contena-Ochsner AG chose deister electronic based on their extensive experience and the successful collaborative relationship built over the years. The partnership between deister electronic and Contena-Ochsner AG initially began in 2000 as part of a project in Zurich where deister electronic supplied approximately 3,000 transponders for their system. This project was particularly characterized by the preliminary development of the current rear comb antennas, which can now be found on thousands of waste disposal vehicles.