Peter Kettig, Project manager Berendsen GmbH West

RFID laundry dispensing system - ideal for laundry dispensing and return of pool laundry, workwear and uniforms.

For laundries, hospitals and care facilities as well as in the industrial sector, supplying employees with workwear, pool laundry and uniforms is often a challenge.

With the teXtag® textile management solution, you can automate the issue, return and management of pool linen, workwear and uniforms and map the entire textile cycle. Both centralised and decentralised issue and return of clothing, the transportation of used workwear to the laundry and the delivery of fresh garments.

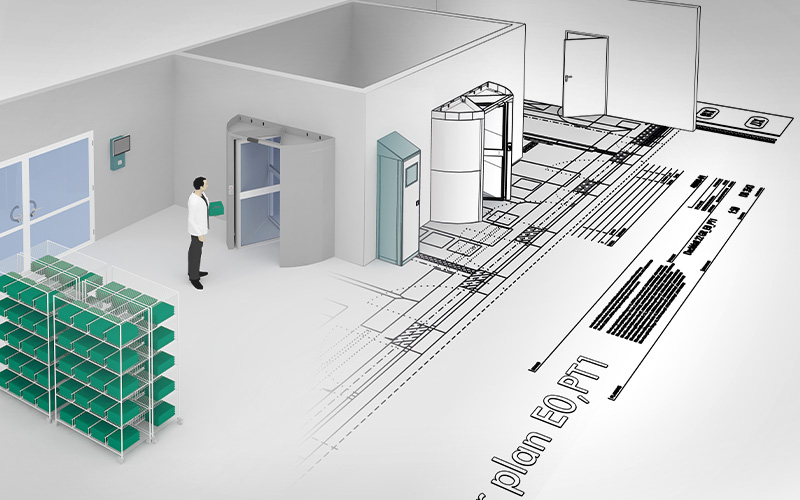

Individually planned room solutions that work like a walk-in closet. When employees enter and leave the supply room, their clothing is automatically registered and accounted for by RFID readers inside the revolving doors.

The intelligent locker systems allow for the decentralised issue and return of textiles, thus reducing staff commuting times enormously.

Our teXtag® solution is the only system that allows parallel access for multiple users and does not require a complicated touch display - open, take out, close and away you go.

The real costs of a system become apparent once it has been in use for a while - leading to much higher costs if the products break down quickly or perform poorly. Highest quality and innovation are our core competences. Highest quality and innovation are our core competencies. This is what we stand for as a company for over 40 years.

From delivery and distribution of fresh clothing to returning and cleaning of used garments in the laundry - we are happy to support you in the individual planning and implementation stages of a laundry distribution system that exactly fits your needs and allows for transparent laundry management.

With teXtag®, we focus on maximum user-friendliness, reliable identification of garments and wearers and a very small footprint.

Test the user-friendliness and performance of our textile management solution live in our demo room - at any time. You can operate and test all products and applications of the solution yourself - from the revolving door and the airlock to the dispensing and return cabinets.

Please feel free to make an appointment for a free consultation and demo!

Long waiting times at the laundry distribution are a thing of the past at Leverkusen Hospital. Since January, nurses, doctors and cooks are utilizing the "texRoom" to supply themselves with workwear. An RFID system automatically detects which items the employees pick up.

The DRK's laundry pool of several hundred polo shirts, trousers and sweatshirts in various sizes is now stored in three laundry cabinets from the teXtag® series.

Berendsen GmbH West, based in Hagen, is a full-service textile supplier for the healthcare sector. With its convenient textile service, the company takes over the complete laundry supply of hospitals, clinics, retirement homes etc. in the middle of Germany.

deister electronic GmbH

Hermann-Bahlsen-Straße 11

30890 Barsinghausen