Peter Kettig, Projektverantwortlicher Berendsen GmbH West

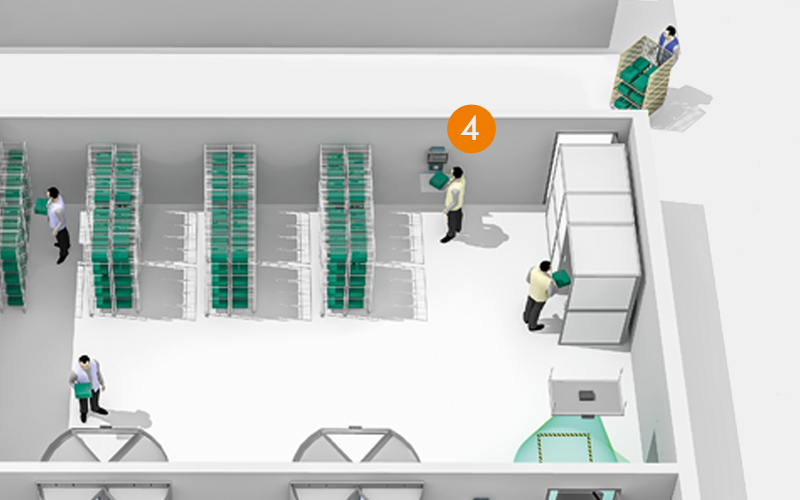

Automatisiertes Textilmanagement

RFID-Wäscheausgabesystem - ideal für Wäscheausgabe und Wäscherücknahme von Poolwäsche, Berufsbekleidung und Uniformen

Automatisiertes, zentralisiertes und dezentralisiertes Textilmanagement

Effizientes Wäschemanagement für Berufsbekleidung und Poolwäsche

Für Wäschereien, Krankenhäuser und Pflegeeinrichtungen sowie im industriellen Bereich ist die Versorgung der Mitarbeiter mit Berufsbekleidung, Poolwäsche und Uniformen oft eine Herausforderung.

Mit der teXtag® Textilverwaltung-Lösung können Sie Ausgabe, Rücknahme und Verwaltung von Poolwäsche, Berufsbekleidung und Uniformen automatisieren und den ganzen Kreislauf der Textilien abbilden: Sowohl zentrale als auch dezentrale Ausgabe und Rückgabe der Bekleidung, den Abtransport benutzter Wäsche zur Wäscherei und die Anlieferung der aufbereiteten Bekleidung.

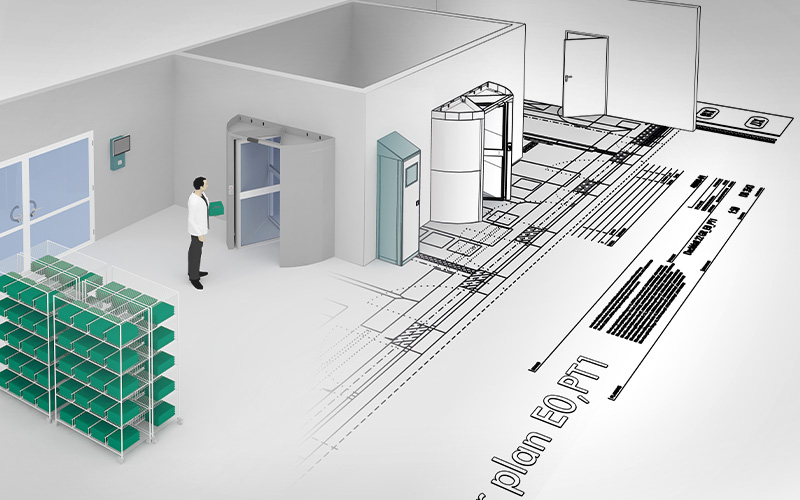

Individuell geplante Raumlösungen funktionieren wie ein begehbarer Kleiderschrank. Beim Betreten und Verlassen des Versorgungsraums wird die Kleidung der Mitarbeiter in den Drehtüren automatisch erfasst und verbucht.

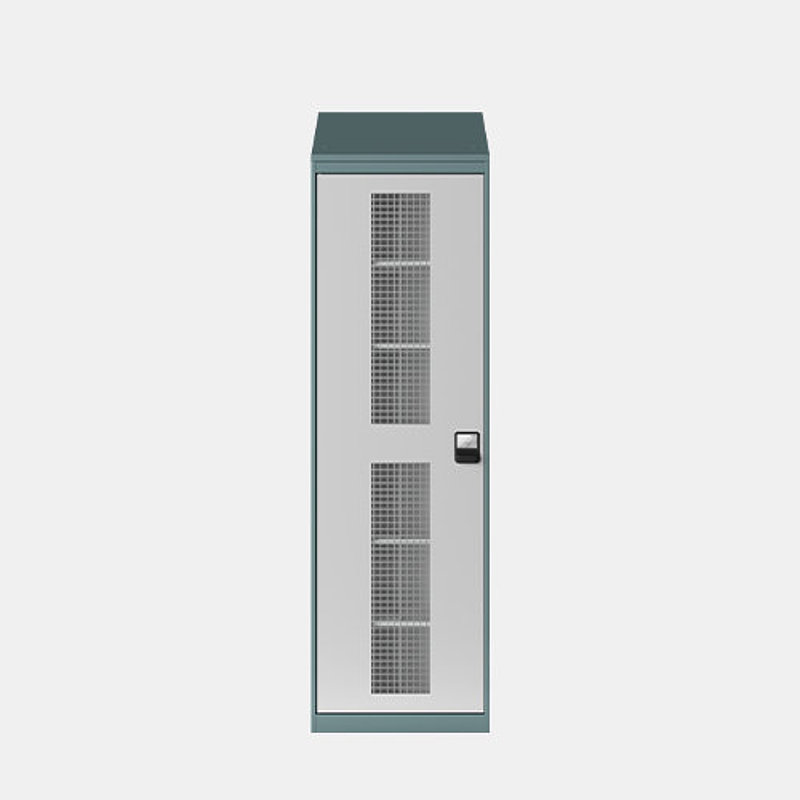

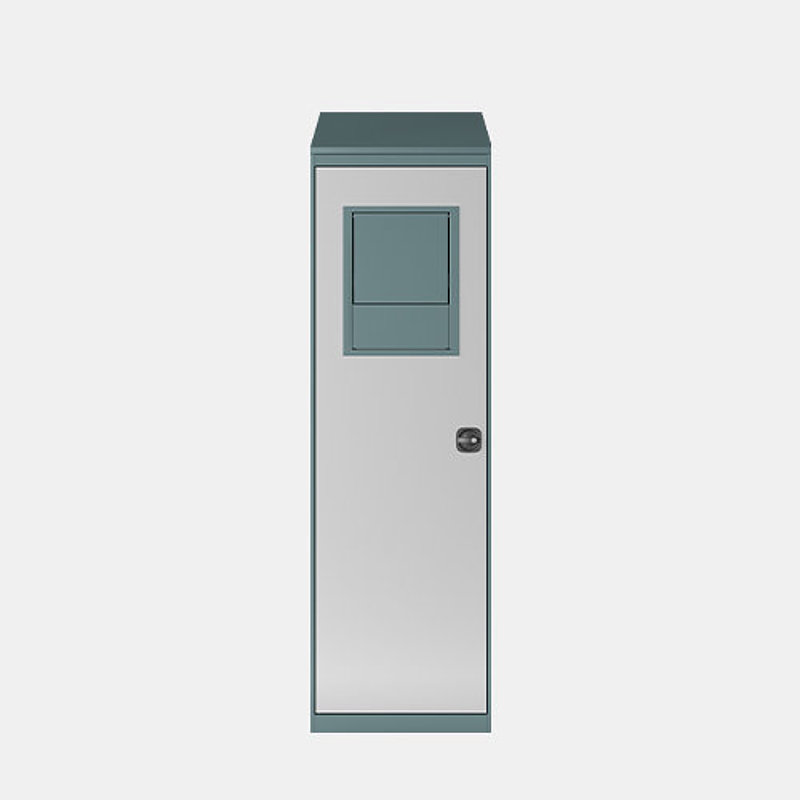

Die intelligenten RFID Schrankfachsysteme ermöglichen die dezentrale Ausgabe und Rücknahme von Textilien und reduzieren somit die Wegezeiten der Mitarbeiter enorm.

- Enorme Kostenersparnis durch Bestandsoptimierung

- 24 / 7 Verfügbarkeit der Wäschebestände

- Reduzierung von Schwund und Verlust der Kleidungsstücke

- Permanente Inventarisierung und Transparenz im kompletten Wäschekreislauf

Lösungsübersicht

Schränke

Schranksysteme für die dezentrale Ausgabe und Rückgabe

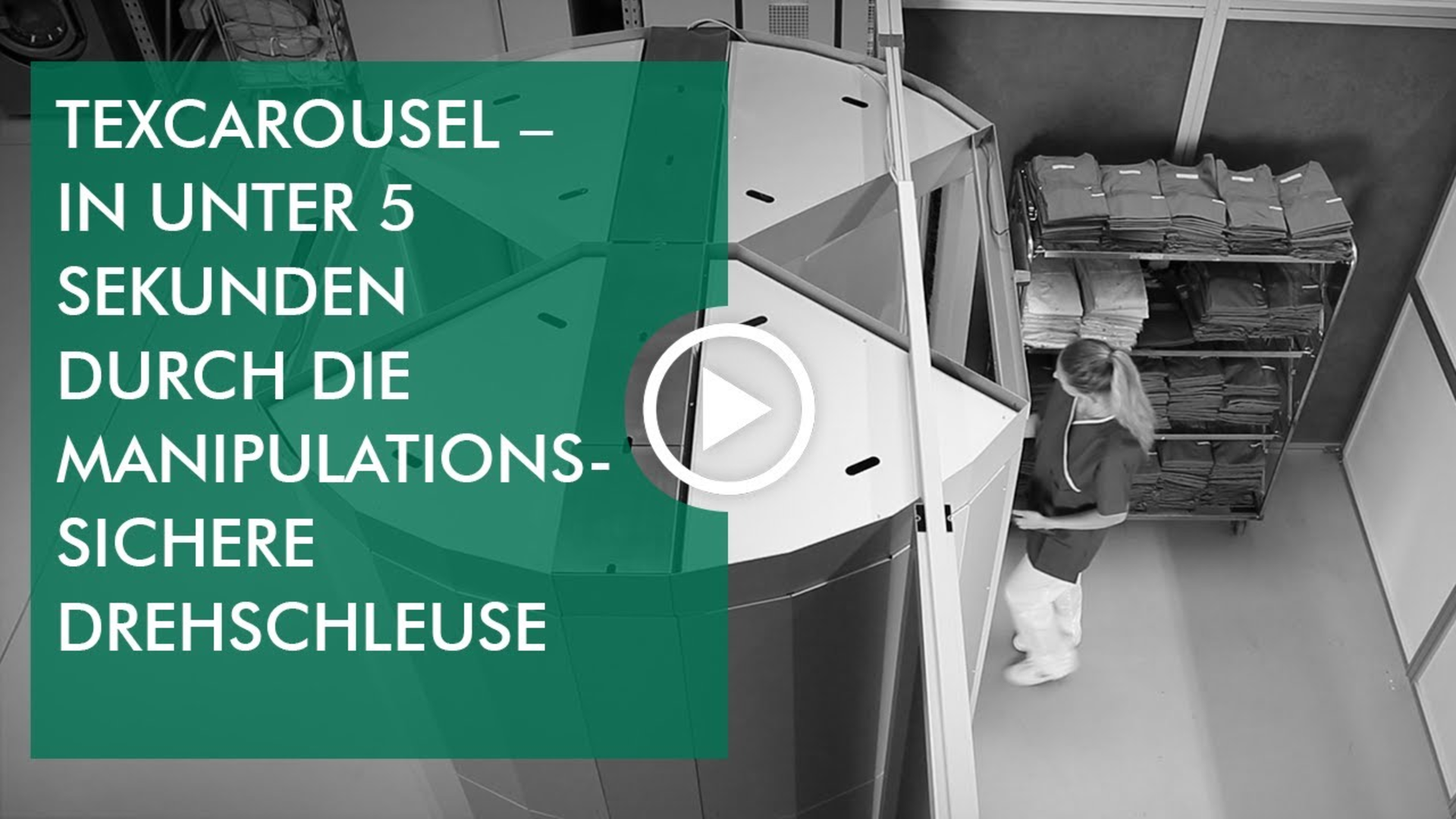

Gates & Schleusen

Zugänge zum zentralen Wäscheausgaberaum

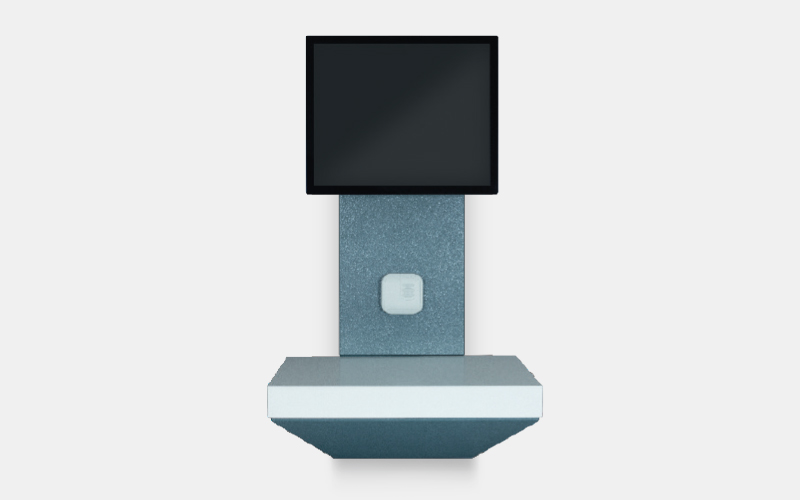

Anlieferung

Buchen frischer Kleidung bei Anlieferung

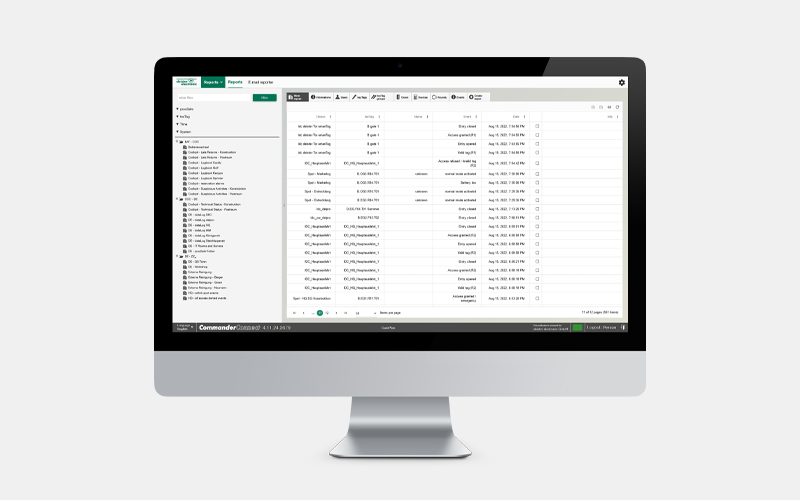

Commander Connect Software

Zentrale Verwaltungssoftware

Vorteile unserer Lösung

Auf der Überholspur

Schnell, einfach und effizient

Unser teXtag® System ist auf Effizienz und Geschwindigkeit getrimmt. Als einziges System erlauben unsere Schränke den Parallelzugriff mehrerer Benutzer und braucht kein kompliziertes Touchdisplay – Aufmachen, herausnehmen, zumachen und los geht’s.

Qualität

Für jahrelangen Dauerbetrieb

Die echten Kosten eines Systems zeigen sich erst nach einiger Zeit im Einsatz – und dann ist es umso kostspieliger, wenn die Produkte schnell kaputt gehen oder mangelhaft funktionieren. Höchste Qualität und Innovation sind unsere Kernkompetenzen, dafür stehen wir als Firma seit über 40 Jahren.

Beratung & Planung

Ihre individuelle Lösung

Von der Anlieferung und Verteilung frischer Bekleidung, bis hin zur Rückgabe und Reinigung der gebrauchten Wäsche in der Wäscherei – gerne unterstützen wir Sie bei der individuellen Planung und Umsetzung eines teXtag® Wäscheausgabesystems, das genau zu Ihren Bedürfnissen passt und Ihnen die transparente Verwaltung Ihrer Wäsche ermöglicht.

Unser Fokus liegt auf der maximalen Benutzerfreundlichkeit, der verlässlichen Erfassung von Kleidung und Kleidungsträger und dem sehr geringen Platzverbrauch des Schranksystems.

Testen Sie jederzeit die Benutzerfreundlichkeit und Performance unserer Wäscheausgabe Lösung live in unserem Demoraum in Barsinghausen. Hier können Sie alle Produkte und Anwendungen der Lösung selbst bedienen und testen - von der Drehtür und der Schleuse bis hin zum RFID Ausgabeschrank.

Vereinbaren Sie gerne einen Termin zur kostenfreien Beratung und Demovorführung!

Videos

Referenzen

Klinikum Leverkusen

Lange Wartezeiten an der Wäscheausgabe gibt es im Klinikum Leverkusen nicht mehr. Seit Januar bedienen sich Pfleger, Ärzte und Köche im „texRoom“. Dahinter steckt ein RFID-System, das automatisch erfasst, welche Teile sich die Mitarbeiter holen.

Pflegeteam Caselato

Für die weiße Weste sorgt nun eine Lösung des RFID-Spezialisten deister electronic: ein modernes Textilmanagement, mit dem die tägliche Aus- und Rückgabe der Berufsbekleidung transparent und effizient geregelt ist.

DRK Schwenningen

Nun findet der Kleidungspool des DRK aus mehreren hundert Polohemden, Hosen und Sweatshirts in verschiedenen Größen in drei Wäscheschränken aus der teXtag®-Serie Platz.

Zahnklinik Witten

Die Berendsen GmbH West mit Sitz in Hagen ist textiler Vollversorger für das Gesundheitswesen. Mit seinem komfortablen Textilservice übernimmt das Unternehmen die komplette Wäscheversorgung von Krankenhäusern, Kliniken, Altenheimen und Co. in der Mitte Deutschlands.

adidas Runners

Für seine Community Adidas Runners hat der bekannte Sportartikel-Hersteller den weltweit ersten Testschuh-Automat in Wien aufgestellt; für die korrekte Erfassung und Rückgabe der Laufschuhe sorgen spezielle Transponder und UHF-Lesegeräte von deister electronic.